PVD Coatings: how and why

PVD, the acronym for Physical Vapor Deposition, indicates a series of techniques for the deposition of thin film coatings.

These methods have been widely used since the late 1960s to create layers of material for applications in both research and in industry, ranging from electronics to mechanics, from construction to fashion, because they allow the composition and thickness of the deposit to be precisely regulated, and thus to obtain systems with special and controlled characteristics.

The market requires innovative products of the highest quality, and this is why PVD continues to find more and more applications in the field of industrial coatings. However, its spread is limited, especially in Italy, by a lack of awareness and its being perceived as new technology despite its decades of history.

PVD technology in brief

In PVD deposition, a material (the target) is brought into the vapor phase so that it can reach the surface of the object to be covered (called the substrate) where it condenses, forming the film. This atom-by-atom deposition mechanism not only improves the adhesion of the film, but allows the use of a wide range of materials to coat various types of substrates, from steel to brass, iron and zamak, but also plastics, glass and ceramics, unlike other technologies that are limited to a few types of metals.

Sputtering, cathode arc and thermal evaporation (often simply called metallization) are the main processes used industrially. They differ in the way in which the constituents (atoms and ions) of the vapor phase are extracted from the target and the energy that is supplied to them. The choice of one method over another is determined by the properties one wishes to obtain, in terms of the compactness, adhesion and color of the film, and by the type of material to be deposited. More specifically:

- Sputtering: the target is hit by a shower of particles coming from an ionized gas (plasma). These “bullets” erode the material and extract the atoms, which will then be uniformly deposited on the substrate.

- Cathode arc: an electric discharge produces localized evaporation of the target, which then generates a flow of ionized material toward the object to be coated. Because they are ions, it is possible to supply them with energy and thus obtain compact and resistant coatings.

- Thermal evaporation (or metallization): the material to be deposited is placed in a crucible and brought to high temperature, causing it to rapidly evaporate and travel towards the substrate.

A vacuum is a necessary condition for being able to trigger these mechanisms. It also aids the transferring of the material, which is not slowed down by air or other fluids, and thus it reaches the surface of the substrate with more energy and adheres to it more firmly. Although creating a vacuum in the process chamber seems like an obstacle, it actually brings about two fundamental benefits:

- it minimizes contaminations, thus high quality coatings are obtained;

- it has a defined, repeatable deposition process, as the vacuum is a well-controlled working condition, as opposed to electroplating, which is very sensitive to ionic concentration and additives, current density, temperature and polarization.

No polluting solutions are used in the PVD processes and the metals used are pure, thus there is no releasing into the atmosphere of environmentally harmful substances during the deposition, which makes it a sustainable technology in keeping with the growing awareness of ecological issues.

Another strength of PVD technology is the possibility of producing composite materials (nitrides, carbides, oxides), i.e. consisting of different elements, by introducing gases that combine with the atoms that are about to be deposited. By doing so, coatings with superior characteristics are obtained, such as the high resistance of nitrides to wear and scratching. It also makes it possible to produce special colors that cannot be obtained with other technologies. It is precisely for these reasons that PVD is sometimes used as a technology that is complementary to other treatments. For example, in some cases an electroplated precoating is applied to obtain a shiny surface and increase corrosion resistance, after which a thin PVD layer is applied to provide hardness and the desired color shade, from straw yellow to gold, from chrome to gloss black, light pink and cherry brown.

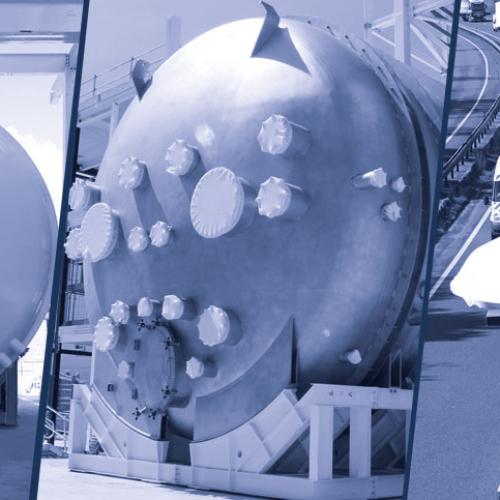

The PVD plant and deposition

A PVD system consists essentially of three parts: the process chamber, the pumping system, and the control electronics. The first two are closely connected with each other; in fact larger chambers, sized according to the shape and size of the pieces to be coated and the desired productivity, require pumping systems with a higher flow rate. The electronics, on the other hand, manage all the system components and control and regulate the various parameters so that the process is stable and repeatable.

One fundamentally important operation done prior to deposition is the preparation of the pieces. Depending on the object to be coated and the materials (for example zamak, brass and plastics), an electroplated precoating or painting may be required to create a surface that is shiny and impenetrable to chemical agents. The cleaning of the pieces is essential in the process chain. This can be done manually or using ultrasound systems. It requires special care, given that when working in vacuum, it is necessary to eliminate as much as possible those substances that could evaporate and slow down the pumping of the chamber or contaminate the process.

The cleaned or pretreated pieces and the frame upon which they are placed, consisting of rotating fixtures designed to obtain an even distribution of the material on a 3D surface, are put into the chamber. After reaching the ideal vacuum for deposition, the sources – the mechanical and electronic devices used to extract the atoms of the target – are turned on. At the same time, if an oxide, a nitride or a carbide is to be obtained, a gas containing oxygen, nitrogen or carbon respectively can be introduced. By varying the gas flow and the rate of extraction of the atoms from the target, it is possible to obtain materials having different compositions, and thus with different physical characteristics and colors. From 0.2 to 5 µm of material are usually deposited, depending on whether the coating is to be decorative or functional. This will affect the duration of the process, which will range from a few minutes to several tens of minutes, also depending on the type of coating desired and the technique used. After this, air is sent back into the chamber and the pieces can be extracted, with no need for further treatments. Disposal operations are also unnecessary, since no waste is produced using this eco-friendly technology.

The apparently complicated PVD process is controlled entirely by the software, which automatically regulates gas flows, pumping, times, voltages and rotation of the pieces, and controls every aspect that is part of the recipe, i.e. the sequence of operations that lead to the final result. With the way modern systems are structured, PVD technology is no more difficult to use than other technologies, such as electroplating or painting.

Like all industrial machinery, PVD equipment also requires maintenance. This ranges from periodic cleaning of the chamber to the replacement of targets, all operations that are simplified by an intelligent PVD system design. It is obviously up to the manufacturer to provide a system that is efficient, accessible and intuitive to use, well-suited to the customer’s needs.

A PVD system is sophisticated and technologically advanced, and this justifies its higher cost. In exchange, you get reliability and versatility, characteristics that allow you to obtain products of greater aesthetic and technical value than those made using more traditional techniques and, above all, to always satisfy market trends and demands. Furthermore, thanks to the wide spectrum of possibilities offered by PVD, new product lines can be envisaged, for markets yet to be explored.

Applications

PVD offers countless possibilities, as practically any material can be deposited: from pure metals to alloys, and from nitrides to carbides and oxides, as well as glasses and ceramics. In addition, the objects to be coated can also be made up of metals, alloys, plastics and glass, and this dramatically increases the fields of application of this technology.

Metallization, or the depositing of a thin layer of metallic material, is often used for protection, shielding or increasing reflectivity, essential characteristics for optical applications such as mirrors for concentrating and deflecting light beams and signals, car headlights, or in electronics. This process is also applicable to plastics and glass, materials that can be easily shaped, so as to combine the advantages of a metal surface with objects with complex shapes. This explains the increasing use of PVD chrome plating in fields such as handles and interiors for auto industry, caps and containers for cosmetics, faucets, taps and utensils for home furnishings, and for accessories such as buckles, hooks, buttons, and costume jewelry for the fashion industry. In these cases, it is also not uncommon to use PVD and PECVD technologies to add an additional thin protective layer of glass with the aim of improving corrosion and scratch resistance.

As the process consists of a jet of material towards the object to be coated, the shape of the object must satisfy certain requirements. Indeed, with PVD it is not possible to coat deep and narrow holes, or to guarantee perfect evenness on internal or difficult to access areas. This problem is usually overcome by hanging the pieces to be coated on rods and mechanically rotating them around several axes, so that they pass in front of the sources of the material, always showing a different area.

PVD is widely used in the making of machining and cutting tools, due to the fact that nitride and carbonitride-based coatings are easily obtained and are characterized by extreme hardness and high adhesion, properties that improve efficiency and lengthen the life of these mechanical components. Again, because of the possibility of producing composite materials, colors such as gold and silver can be created without having to use these precious metals, and it is also possible to find new shades and highlights that best suit the trends and fashions of the moment. In the decorative field, straw yellow, black, chestnut or rose gold are new colors that combine elegance and innovation with the charm and the tactile feel that only metal can offer, while maintaining its shine and resistance to scratches and abrasion. The versatility and quality of PVD coatings are certainly among the most important strengths of these types of applications.

The installation of one of the largest space simulators in Europe has just been completed at the Rutherford Appleton Laboratory (RAL) in Great Britain.